LASER CUTTING

What is laser cutting?

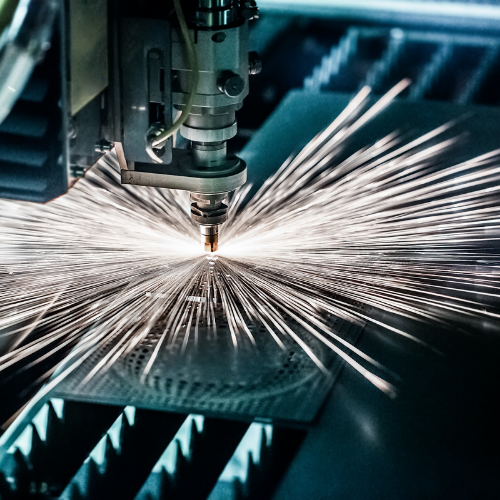

Laser cutting is an industrial manufacturing process that allows fine and accurate cuts to be made to materials. The laser cutting machine is designed to create fine detail in numerous mediums including sheet metal, steel, stainless steel, mild steel, copper as well as aluminium and brass with DV Machining and fabrication Bystronic Fibre Laser. The CO2 beam melts materials to separate the medium into a fine, polished product. As a result, the laser can either cleanly cut material or create engravings.

What is the process?

Laser cutting is an intricate process that uses a high output of power, finely directed through a laser, to produce a high-quality edge for the material it is cutting. A CAD file is sent directly to the machine to guide it. The heat produced is directly applied to the given medium and melts the material away, leaving a clean cut to the finished product. Laser cutting is one of the most energy-efficient ways of manufacturing in the UK and can easily be ordered online through local, trustworthy companies such as DV Machining and Fabrication.

What can laser cutting be used for?

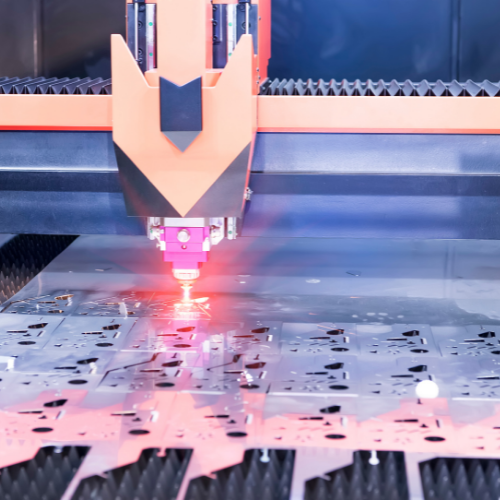

Laser cutting is a widely used manufacturing process that is ever-growing in the engineering world. Laser cutting can be used for various jobs, creating instruments needed in fields such as automotive, the food industry, aerospace and electronics. Laser cutting is often used for small, elaborate detail that cannot be achieved by hand or other machinery. Small, fine cuts can be made by the laser piercing single or numerous layers in the material to create details in parts and instruments. DV Machining and Fabrication work with many high-profile companies offering laser cutting as the first step in their process with over 1000 different components including supply into Earthmoving.DV can cut within the area of 3m x 1.5m,and we can produce components as small as 3.5mm wide. Their high quality and reliable laser cutting produces parts for widely renowned and important sectors such as the food industry. In this field, processing machinery and equipment is in high demand; DV Machine and Fabrication laser cutting offers a quality of service that is fast and reliable within this industry.

Who would need to use laser cutting?

Many companies and industries rely on laser cutting for business purposes. DV Machining and fabrication cut to specific customer requirements to ensure the initial part of any manufacturing process is right. Following different dimensions and tolerances, DV Machining and Fabrication will produce an excellent and accurate product to your necessities. Many manufacturing companies need laser cutting for prototype models. Laser cutting is a fast and efficient way of creating small, detailed models that represent possible designs and ideas. The precise nature of laser cutting ensures a polished and accurate model of any product. Laser cutting is far more accurate and precise than plasma cutters, allowing tight tolerances and a quality finish. Plasma cutters have a small kerf compared to laser cutters; therefore, less metal is lost during profiling. Laser cutting also offer a slightly higher tolerance, preventing metal distortion and ultimately creating a better finish, imperative to any OEM or manufacturing designs. The higher tolerance also ensures thinner sheets of metal can be engraved or cut without damaging the material. As a result, DV Machining and Fabrication flexible laser cutting services are perfect for any manufacturer.

Need An Engineer You Can Trust?

DV Machining and Fabrication, Stoke-on-Trent, Staffordshire,Newcastle-under-Lyme, Cheshire, Birmingham, Manchester, London, UK